I once read a fortune cookie that said, Discontent is the first step in the progress of a man or a nation. In this case, discontent was the first step in the progress of a shared off-site optical lab.

|

| All images courtesy: Andrew Pinkham Licensed optician Craig Dyer works full time at our shared off-site optical laboratory. |

About six years ago, I was commiserating with my colleague, optometrist Jay Friedman. Dr. Friedman, who lives in the next town over, had been something of a mentor to me when I first opened my practice. He and I were discussing how dissatisfied we were with our individual in-office optical labs. The manual technology we each had at the time was noisy, messy, slow, and occasionally produced inconsistent lens products. It was also challenging and time-consuming to handle some of the more complex jobs. We both agreed we needed to upgrade our practices to more modern patternless edging.

To add to our lab woes, we each had a fabricating, or bench, optician and two or three dispensing opticians. In comparing notes, we discussed that our bench opticianswho generally like to stay in the back and work with lenses and machinesdidnt have enough jobs to keep them busy full time, and they had to spend part of the time out front dispensing to patients. Also, although we both have large partnership practices, neither of our practices had enough volume to justify the investment required for top-of-the-line lab equipment.

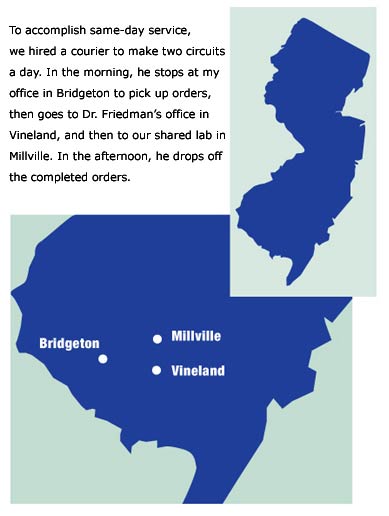

Then an opportunity presented itself. In our rather rural county in southern New Jersey, there are three large towns that form something of a triangle. My practice is in Bridgeton, which is about 15 miles from Dr. Friedmans practice in Vineland. In the third town, Millville, an older O.D.s practice became available right around the time that Dr. Friedman and I were analyzing our optical problems.

|

We struck upon the idea of joining forces and taking over the optometric office in Millville. There, we would install a shared off-site but functionally in-office optical edging laboratory.

Home Field Advantages

So thats what we did. We bought the practice and the building, and set up a lab inside.

Specifically, Dr. Friedmans practice and my practice entered into partnership, a limited liability company, in which each practice owns half the assets and shares half the responsibility. Thats written into our agreement, which was fairly easy to set up with the help of an attorney. Technically, the optical lab is a separate business from each of our practices.

To equip our new lab, we decided to pick and choose the best of what we had among our existing equipment, and then liquidate the rest. With those funds, we bought a state-of-the-art automated patternless edger, as well as a pattern-maker and lensometer. (We kept one of our old edgers around for a while as a backup. When we realized how reliable the new edger was, we got rid of the backup, too.)

|

| Separately, neither of our two practices could justify the investment in high-tech equipment needed for a stand-alone lab. But together, we were able to do it. |

We figured we would realize several advantages by sharing our own off-site optical lab:

- Quality. We could keep a closer eye on quality control by having the lab under our direction (as opposed to sending out jobs to other labs). Plus, the new equipment and the attention of a full-time lab optician would take us a leap forward in quality, compared with our previous in-house lab capabilities.

- Convenience. We might not be able to turn around orders in about an hour, but we could almost always provide same-day service, or at least next-day service.

- Patient retention. Improved quality, service and greater convenience would add up to higher patient satisfaction, so most patients wouldnt be inclined to go elsewhere.

- Savings. By fabricating lens orders in-house (especially for high-end lenses), we can save a lot of the extra expense of sending lens orders to outside labs. In addition, by sharing the salary of a single lab optician to handle all our in-house orders, we would save on the expense of employing individual opticians in each of our practices. Plus, moving our in-office labs to an off-site location would free up precious floor space in each of our offices.

Nuts and Bolts

We had to figure out several practical considerations to get this operation running.

For one, I was in between bench opticians at the time, so Dr. Friedman moved his very skilled fabricating optician into the full-time position at the new lab.

To achieve same-day service, we had to have someone to run back and forth from my office in Bridgeton to Dr. Friedmans office in Vineland, and carry the orders to the lab in Millville, then make a return trip later in the day to drop off completed orders.

Fortunately, I knew an energetic fellow who drove a school bus. We hired him to make the rounds between our offices and the lab, in between his early morning and mid-afternoon shifts of driving the school bus. (Hes now retired as a bus driver, but he still makes his rounds for us.) This means that a patient can come in for an appointment in the morning, for example, order a new lens in her same frames, and we can have it back and ready for her by that afternoon.

Another option to take care of those urgent or emergency situations: Patients can make an appointment and drive directly to our optical lab and have the order completed while they wait. (In New Jersey, opticianry is a licensed profession. A licensed optician is permitted to dispense spectacles directly to the patient here.) Most patients who want that fast turnaround time are willing to make the trip to our lab because they would have to drive at least as far, or farther, to get to a one-hour commercial shop.

|

| Ive known optometrist Jay Friedman since I opened my practice. We found its easier to be partners when youre already friends. |

One additional note about speed and turnaround time: We went into this venture with the expectation that we would eventually be able to do remote tracing in our offices, then the optician could finish the lens in the lab. But to do so, we needed high-speed Internet service. Unfortunately, we didnt get access to high-speed Internet in our area until recently. So that hope may soon become a reality.

In our labs inventory, we stock polycarbonate and regular plastic lenses in single-vision. For bifocals, multifocals and progressives, we order overnight delivery of uncut lenses. The lab is outfitted with a tinting unit and similar equipment, so we can do tints and coatings, too. However, we dont keep an inventory of frames at the lab.

The optician keeps track of which orders come from which practice. At the end of the month, the optician tallies up the fees and materials for each job and passes the list to Dr. Friedmans practice administrator, who generates a bill for each of our practices. (Our practices take turns every few years doing the billing and managing the paperwork.) Single-vision lenses, which are part of the labs inventory, are billed to each of us. For any other kind of lenses, as well as frames, each practice orders and pays for these separately and has them shipped to the lab as needed.

Also, to make it work, each of us needs to pay our bills to the business on time, just like we would for any outside business.

Lessons Learned

We never really had the intention of getting into this partnership to make a profit. So far, weve only broken even. Our main concerns were to be competitive with commercial shops and, more importantly, to control the quality we offer to patients.

(Its likely that if we added another practice into the lab business, we could very well realize a profit, as long as our optician could maintain the volume and quality weve received up to now.)

Still, were doing better than if we sent these orders out to another optical lab, especially for high-end lenses. Of course, higher-end products tend to generate higher profits. For example, a high-end progressive lens might cost $100 or more for fabrication at a quality lab. But we can cut that cost by $30 or more by doing it in our lab. For single vision lenses, however, we do just a little bit better than breaking even.

Then again, if the lab is idle for any reasonthe equipment breaks down, the optician gets sick or goes on vacationwe have a double-edged problem. Were paying for services that arent generating revenue, and were temporarily unable or delayed in providing those services to patients. Still, this happens so infrequently that it hasnt become too much of a problem.

Again, opticianry is a licensed profession in our state. That means that a skilled fabricating optician earns something like $20 an hour. But this employee, if he or she is highly skilled, may well be worth it, even with automated equipment.

As Dr. Friedman recently said to me, To get the most out of a patternless edger, along with all the nuances inherent in making difficult or complex prescriptions in todays upscale high-technology eyewear, you still need a qualified, experienced technician to get the most out of the new technology. I think its a mistake to make the investment of a patternless edger and then hire an inexperienced employee for a few bucks an hour. I would be fearful of the work that an inexperienced, low-paid person would turn out on a patternless edger.

On a side note: We try not to micromanage the optician and the lab. His main contacts with our offices are our practice administrators. They handle any of the day-to-day concerns. Every few months well call or drop by to check in. Otherwise, we let these able employees manage without unwanted intrusion.

We also realized that its best that the lab is in a separate, off-site location, and not connected to either practice. This way, neither of us feels an obligation or a temptation to run the lab under our very own eyes.

Benefits of Sharing an In-Office Off-Site Lab

Close Enough

Two reasons why this lab works smoothly for us are that we dont accept many vision plans, and that we are friends as well as partners.

An optometric practice that relies heavily on vision planswhich require you to send the script to their lab for fabricationmay have a tough time justifying the expense for its own fabricating lab. To that office, we would advise that it make a careful analysis of how many jobs it could do in-house and how much savings it might realize from a jointly-owned laboratory.

As partners, we truly act in each others best interest. Dr. Friedman and I have our practices close enough that we can work together like this, but not so close that were vying for the same patient population. Even so, we occasionally refer patients to one anothers practice when its in the patients best interest. And, well cover for one another when one of us goes out of town, and make sure those patients return to their original doctor.

In short, this lab experiment hasnt netted us a fortunenevermind the fortune cookiebut it has been a rewarding experience to keep us competitive, and to provide improved quality and services for our patients.